Wabwino Kwambiri Ferro Silicon tinthu Poponya

ntchito

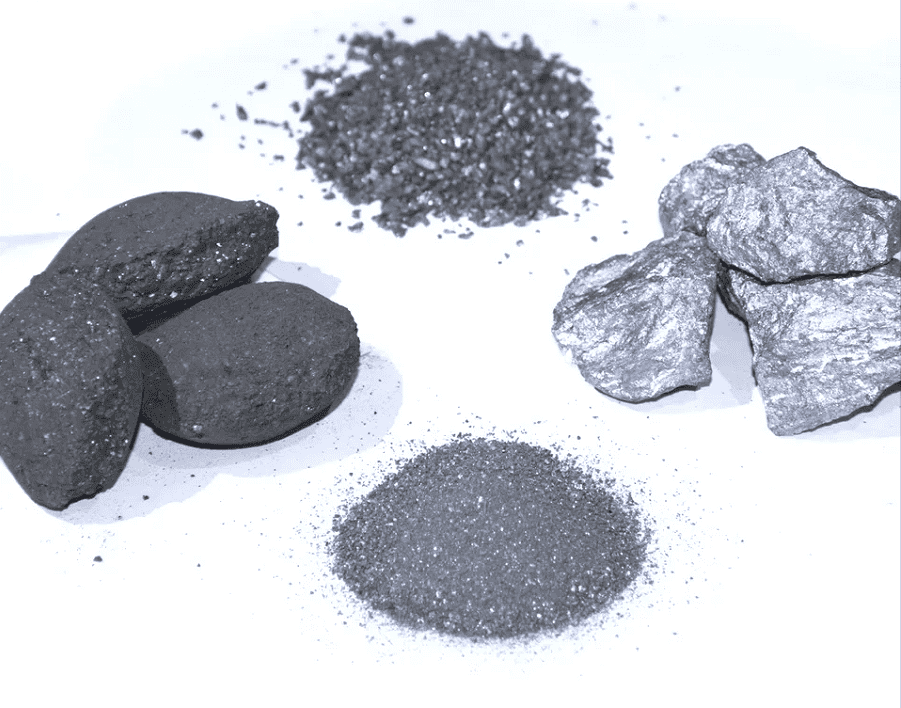

(1) Ferro pakachitsulo particles sangagwiritsidwe ntchito pamakampani opanga zitsulo komanso ngati zinthu zomwe zimagwiritsidwa ntchito zitsulo mumakampani opanga chitsulo. Izi ndichifukwa choti tinthu tating'onoting'ono ta ferro silicon titha kugwiritsidwa ntchito ndi opanga chitsulo kuti m'malo mwa inoculants ndi spheroidizers. M'makampani opanga chitsulo, mtengo wa ferro silicon particles ndi wotsika kwambiri kuposa wachitsulo ndipo umasungunuka mosavuta, zomwe zimawapanga kukhala apamwamba kwambiri. Mkulu khalidwe ferro pakachitsulo tinthu inoculant ndi yunifolomu tinthu kukula ndi zabwino inoculation zotsatira pa kuponyera angalimbikitse graphite mpweya ndi spheroidization, kupanga izo zofunika metallurgical zakuthupi kubala ductile chitsulo.

(2) Amagwiritsidwa ntchito ngati deoxidizer ndi alloying wothandizira pamakampani opanga zitsulo. Kugwirizana kwamankhwala pakati pa silicon ndi okosijeni ndikwambiri, kotero tinthu tating'onoting'ono ta ferro silicon ndizomwe zimawononga kwambiri popanga zitsulo kuti pakhale mpweya komanso kutulutsa mpweya. M'makampani opanga zitsulo, nthawi zambiri amagwiritsidwa ntchito ngati chotenthetsera kapu ya ingot kuti apititse patsogolo ubwino ndi kubwezeretsa kwa ingot pogwiritsa ntchito chikhalidwe chakuti njere za ferrosilicon zimatha kutulutsa kutentha kwakukulu kuchokera ku ene kuyaka kutentha kwakukulu.

Ferro Silicon tinthu topanga zitsulo zosapanga dzimbiri

1. Mtengo wotsika komanso wosavuta kusungunuka

ferro pakachitsulo particles sangagwiritsidwe ntchito mumakampani opanga zitsulo komanso m'makampani opanga zitsulo, nthawi zambiri amagwiritsidwa ntchito zitsulo zachitsulo, makamaka chifukwa tinthu tating'onoting'ono ta ferro tingagwiritsidwe ntchito ndi opanga chitsulo m'malo mwa inoculants ndi nodulators, mu makampani opanga chitsulo, mtengo. wa ferro silicon tinthu tating'ono kwambiri kuposa chitsulo, ndipo mosavuta kusungunuka, ndi ferroalloy mankhwala ndi kuponya mphamvu.

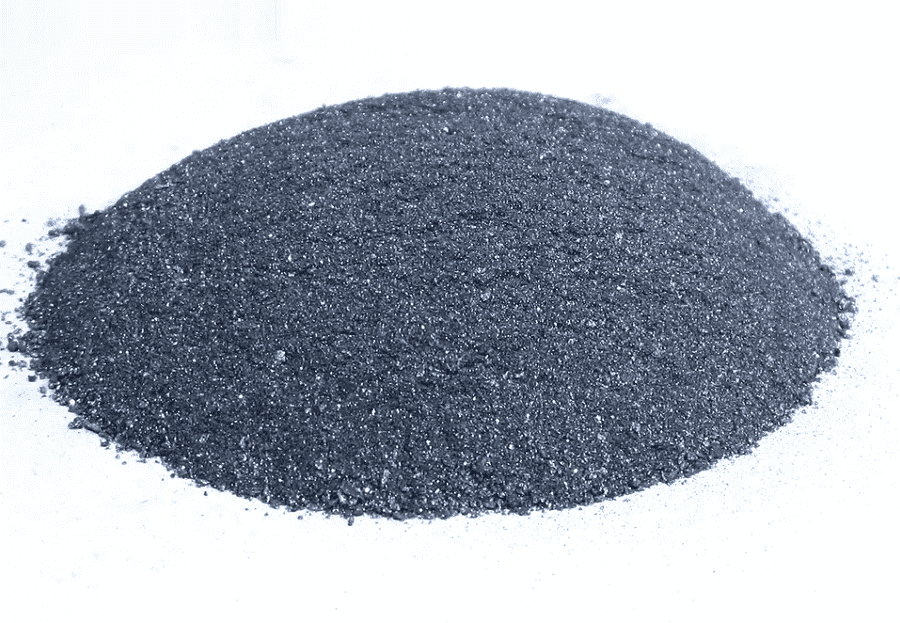

2. Uniform tinthu kukula

Ferro Silicon particles alibe ufa wabwino, khola inoculation zotsatira, ndi kachitidwe kakang'ono kutulutsa slag. Cholemera kwambiri ndi chakuti ali ndi makhalidwe a ma inoculants ena ndipo ali ndi ndalama zochepa.

3. Good elasticity ndi pulasitiki

Kutanuka kwake kocheperako kumachitika chifukwa chopindika pang'ono, ndipo kulimba kwake kumakhala kokwera kangapo kuposa zida wamba zachitsulo. Tinthu tating'onoting'ono ta ferro tilinso ndi kukana kwamphamvu kwa dzimbiri, ndipo wosanjikiza wake wotchingira woteteza amatha kuletsa dzimbiri pamwamba pa kuponyera.

4. Kuchita bwino

Tinthu tating'onoting'ono ta Ferro silicon tili ndi zida zabwino zopangira makina, zimatha kumaliza mwachangu ntchito zovuta kukonza, ndikukhala okhazikika komanso kukana kuvala, komanso moyo wautali wautumiki. Izi zikutanthauza kuti, tinthu tating'onoting'ono ta ferro silicon tili ndi zida zabwino zamakina komanso pafupifupi zotsalira za zero, zomwe zimawapangitsa kukhala zida zoyenera zoponyera makampani oponya.

5. Zinthu zabwino kwambiri za thermoplastic

Ferro silicon particles ali ndi zinthu zabwino kwambiri za thermoplastic, zimatha kukana kupindika pansi pazikhalidwe zosiyanasiyana za kutentha kwambiri, ndipo zimatha kukhalabe ndi mphamvu pakatentha kwambiri, zomwe zimawapangitsa kukhala oyenera kugwiritsidwa ntchito popanga ma thermoplastic castings.

Chemical element

| Chinthu% | Si | P | S | C | AI |

| ≤ | |||||

| FeSi75 | 75 | 0.03 | 0.02 | 0.15 | 1 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.15 | 0.5 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.1 | 0.1 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.05 | 0.05 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.02 | 0.02 |

| FeSi72 | 72 | 0.03 | 0.02 | 0.15 | 1 |

| FeSi72 | 72 | 0.03 | 0.02 | 0.15 | 0.5 |

Zindikirani: Kupanga kwamitundu yosiyanasiyana ya silicon calcium alloy malinga ndi zomwe makasitomala amafuna